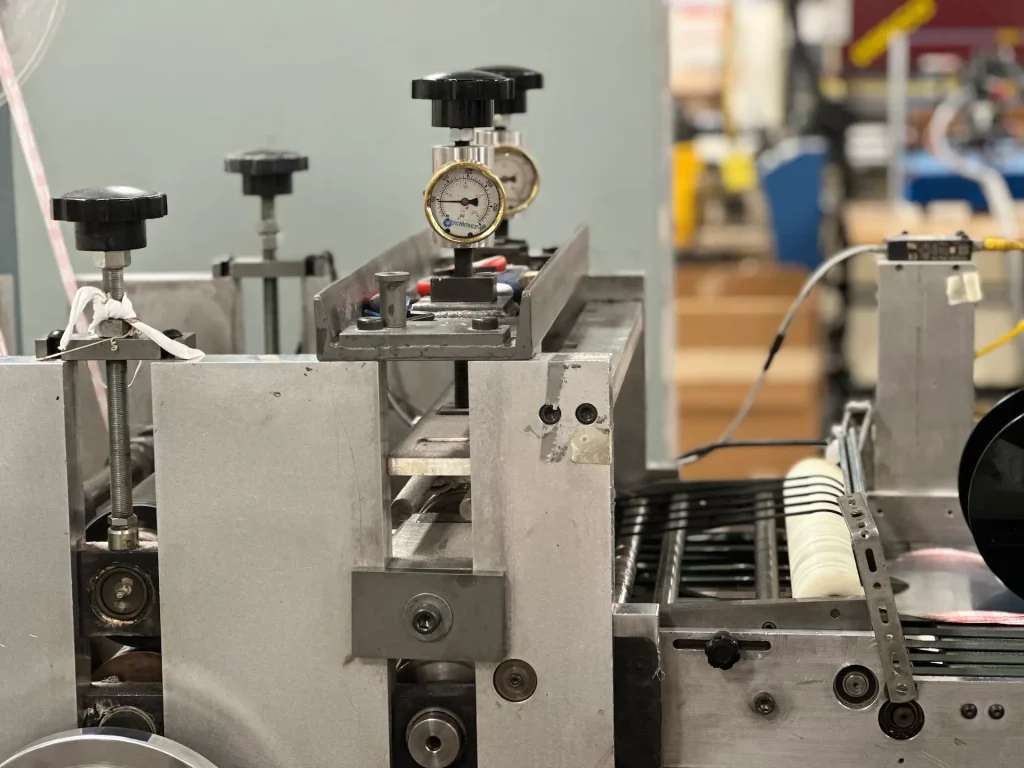

Metal is notoriously one of the most difficult materials to die cut, but with over 75 years of die-cutting experience, our team at Colvin Friedman has the expertise to adjust and accommodate your specific needs. Whether you are manufacturing a specialty product component or require tight tolerances for a large production order our custom metal die-cutting process is designed to assist our customers, no matter their industry.

Or call Josh at (707) 769-4488

Design the die-cut design and choose the die-cut material and method

Dies are created by world class die makers

Ensure initial designs pass all quality tests before mass production

Efficiently produce products to meet customer deadlines and quality standards

High quality user packaging and shipping to distribution centers

Integration with your inventory system to maintain desired stocking levels

01

At the beginning of every custom metal project, we consult with the client on their component. If the client does not have an existing prototype, we will create one to guarantee the design’s quality and make adjustments as necessary. For metal projects, we go to especially great lengths to select the proper material and match it to an appropriate cutting method. We consider details such as the size of the component, the force of the die on impact, and the potential need for die maintenance to avoid issues such as cracking or dulled machinery down the line.

02

Once the design is set, die creation is carried out by some of the top die makers in the world. Depending on the metal being cut, materials like D2 tool steel, A2 tool steel, or carbide are used when molding dies to allow for the cleanest possible cut. Additionally, dies may be outfitted with specialized coatings to reduce friction or increase hardness. Dies may also undergo surface treatments like carburizing or nitriding for similar purposes as necessary.

03

Once dies are created, we generate small, initial production to guarantee the quality of the product, avoid burring, and optimize the settings and alignment of the dies. We perform tolerance level tests, fit and function tests, and overall dimensions tests. All final production approvals are customer-dependent and we encourage clients to perform their own independent tests.

04

Following customer approval, we begin the full production. Our QMS procedures continue running throughout the production to protect against material buildup, die wear, or cracking in the metal. We continually lubricate the system to avoid unnecessary friction, while using cooling sprays to maintain optimal operating temperatures. Our computer numerical control (CNC) technology helps keep our machines calibrated to exact standards, ensuring each product is smoothly cut and of the highest quality.

Or call Josh at (707) 769-4488

As metal is a more difficult material to cut, varying in hardness, thickness, and flexibility, proper die-cutting method selection is crucial to ensure quality products. While most metals may require flatbed die cutting for their ability to handle denser materials, some metals or metal foils, if flexible enough, may benefit from rotary die cutting to achieve an expedient production run.

Suitable for high-volume orders, providing economies of scale

Consistently high precision, ideal for complex and detailed designs

Efficient material utilization, reducing waste and costs

Faster turnaround times for large orders

Higher setup costs, making it less economical for small batches

Limited to metals in roll form, reducing material options

Changes in project scope or design can be costly and complex to implement

Typically requires a long-term commitment due to setup investment

More adaptable for low to medium volume without high setup costs

Capable of handling a wider variety of metals and thicknesses

Flexibility in setup allows for customization and changes in design

Often more cost-effective for short runs and prototypes

Slower production rates can lead to longer turnaround times

Higher material waste due to spacing between cuts, affecting cost

Operation can increase labor costs due to material handling

Less suitable for very high-volume jobs due to slower speeds

Our team at Colvin Friedman most commonly cuts thinner metal or metal foils for custom projects. These foils come in several different varieties, have different strengths, and are each used for a multitude of purposes.

Below we’ve outlined a description of each, including some common uses and the preferred die-cutting method.

Aluminum Foil

Copper Foil

Brass Foil

Aluminum Foil is valuable for its lightweight and corrosion-resistant qualities. It is soft, malleable, and incredibly flexible, making it ideal for die-cutting.

Copper Foil has a red-brown color and is more rigid than aluminum foil. It is a great thermal and electrical conductor and is corrosion-resistant.

Brass Foil is an alloy of copper and zinc and has a gold-yellow color. It is stronger than copper, but is more difficult to cut. The hardness may vary based on the ratio of copper to zinc.

~0.006 mm – ~0.2 mm

~0.018 mm – ~0.127 mm

~0.01 mm – ~0.1 mm

The metallic foils below are less commonly used in die cutting, but can be cut in special applications. They are generally much stronger and optimal for heavy-duty usage, but far harder to handle.

Stainless Steel Foil

Nickel Foil

Titanium Foil

Stainless Steel Foil is an alloy foil made up of 10.5% or less of chromium. It is corrosion-resistant and very hard, making it challenging to handle.

Nickel Foil is available in a pure form or as an alloy. It is particularly corrosion-resistant in alkaline environments and is relatively flexible and stronger than copper.

Titanium Foil is particularly difficult to cut, but it is valued for its high strength-to-weight ratio and resistance in chloride environments.

>0.01 mm

~0.01 mm – ~0.1 mm

>0.013 mm

Flatbed Die Cutting

Flatbed Die Cutting

Flatbed Die Cutting

As these metals are highly valuable, they are even less frequently die-cut. However, they are useful for a number of electronic and other specialized applications outlined below.

Gold Foil

Silver Foil

Gold foils are available as an alloy or in pure form. They are prized for their malleability, ductility, and corrosion resistance. Due to its softness, it is easy to die-cut.

Silver foil is an excellent electric and thermal conductor, making it useful in a variety of electrical applications. It is also a high-value material, but, like gold, it is easy to cut because of its softness.

~0.0127 mm – ~0.127 mm

~0.0127 mm – ~0.254 mm

Rotary or Flatbed Die Cutting

Rotary or Flatbed Die Cutting

Composite metallic foils are thin sheets of metal that are often bound to a supporting substrate like paper. They are versatile, easy to cut, and are frequently used for applications like packaging.

Aluminum-Laminated Foil

Copper-Laminated Foil

In Aluminum-Laminated Foil, the metal layer may be bonded to a substrate of paper or plastic. It is flexible and soft, making it easy to handle in die-cutting.

Copper-Laminated Foil is structured similarly to Aluminum-Laminated Foil. Its layer of copper is quite thin, giving it flexibility, and is useful for electronic conductivity and shielding.

~0.01 mm – ~0.1 mm

~0.025 mm – ~0.254 mm

Rotary or Flatbed Die Cutting

Rotary or Flatbed Die Cutting

Below we’ve outlined our production capabilities for cutting custom metal. We can cut projects that fit within these bounds, but we are generally flexible. If you have a project whose component is far outside these specs, we will refer you to someone who can cut it.

Maximum Product Width

Maximum Product Thickness

Tolerance Level

Maximum Production Capacity

Average Lead Time

16 inches, we can slit down larger jumbos

.015 inches, however, there is flexibility with different materials

Can get down to ±0.005 inches

40,000 units/hour (size dependent)

3 weeks

40 inches

.5 inches, material dependent

±0.010, material dependent

2,000 – 4,000 parts/hour (size dependent)

3 weeks

If you would like more information about our custom die-cutting services, process, or product capabilities, please use the number below to call our Vice President, Josh Rodman. If you would like to receive a free project quote, click the button below.

Or call Josh at (707) 769-4488

We have been a leading provider of die cutting services for over 75 years. Trust us to provide the customer service of a small business with the capabilities of a large organization.

1311 Commerce Street • Petaluma, CA 94954

Copyright © 2025 Colvin Friedman Company. All Right Reserved.