Die Cutting and Converting

In order to create a complex and unique product, it is necessary to use a custom die cutting service. The die cutting industry is extremely complex, and uses many different techniques to create a finished project. Converting is a process that aims to increase speed, simplicity, and performance during a die cutting operation. It helps to find faster ways of completing a project, without compromising quality.

In order to create a complex and unique product, it is necessary to use a custom die cutting service. The die cutting industry is extremely complex, and uses many different techniques to create a finished project. Converting is a process that aims to increase speed, simplicity, and performance during a die cutting operation. It helps to find faster ways of completing a project, without compromising quality.

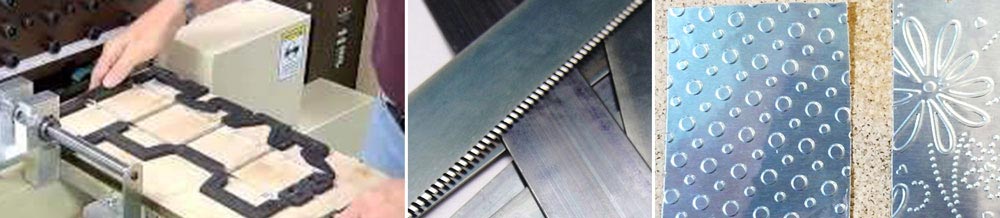

Converting is a machining process that changes a part into a finished product that has a higher value than the original material. It is the psychical action of die cutting and is commonly associated with popular cutting disciplines. Converting disciplines are used to die cut different types of products, and are often used together to obtain a certain effect. The main techniques are: creasing, scoring, perforating, debossing, and embossing. All conversion disciplines help to complete all die cutting and die making endeavors.

- Scoring: A score is considered a fold or indent generated by a knife being pushed into a material. Most scoring procedures only penetrate the substrate partially, or no more than fifty percent. There are many benefits of using a scoring knife in a die cutting operation. First, the resistance to folding is much less than an alternative crease. Secondly, the score creates a very accurate, square folded profile.

- Creasing: Creasing is the preferred method of folding. This method creates a smooth spine fold and is often preferred over scoring. Scorings will create a stronger fold, but creasing creates a more visually pleasing, finished project.

- Debossing: Debossing is known as the opposite of embossing, and leaves an imprinted design into the material. The final product will have a depressed imprint of the logo or pattern.

- Embossing: Embossing is a raised design or pattern that is pressed into a material during the die cutting process. Embossing requires both a male and female die requires multiple die charges.

- Perforating: Perforating die cutting leaves a perforated outline of a shape or design. This is commonly found in items that can be torn off, like a coupon or ticket stub.

Custom Die Cutting Service

Custom material converting services are able to meet the demands of many customers. Converting can help to achieve specific slitting, cutting, and rolling needs. A die cutter, with converting capabilities, is able to score any material to desired specifications. If you are looking to learn more about custom die cutting services, it is best to contract a local business in the area. Experts in the field of custom die cutting are the most well equipped resources of information.

Related Reading- What is Thermal Die Cutting?Talk to your local die cutting service to find out what process would be best for you and your company.

- Getting to know the Flat Bed Die Cutting Process

- Steel Rule Die Cutting